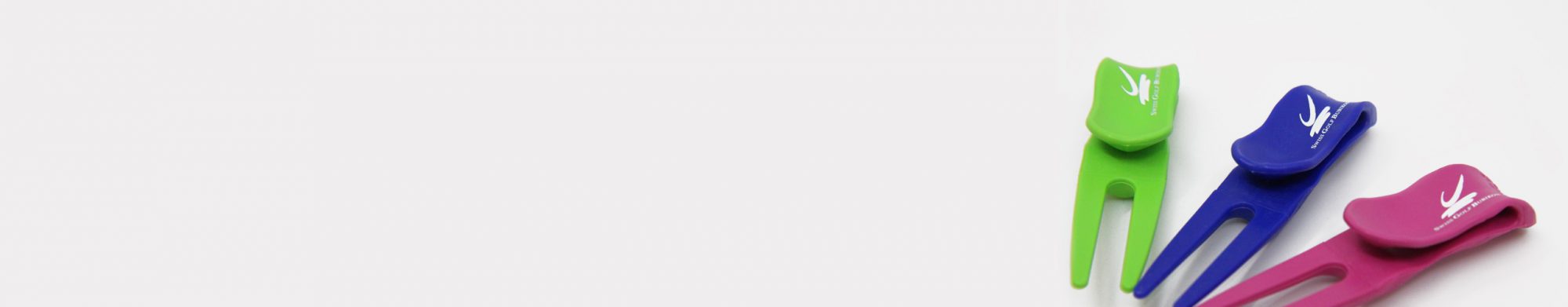

Pad Printing

This printing method roots from the watch and ceramics industries. The Decalcier process, which was already well-know and used in the Swiss watch industry, was a direct precursor to pad printing. The Decalcier method involves using a gelatin pad to apply color to watch faces.

Pad printing can be used when other printing processes cannot. Over time, this method has captured a large section of the market. In the late 1960s, pad printing was found to be an option for new applications and the whole process was modernized with the use of silicone pads and newly developed machinery.